Functie

(1) Spoelmateriaal rechttrekken en nivelleren;

(2) Synchroon laden en snijden van materiaal

(3) Riemaandrijving en automatisch laden van materiaal

snelle details

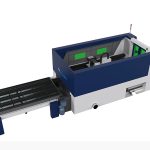

Toepassing: lasersnijden

conditie: nieuw

Lasertype: vezellaser

Toepasselijk materiaal: metaal

Snijdikte: 20 mm

Snijgebied: 1500 * 3000 mm

Snijsnelheid: 35 m / min

CNC of niet: Ja

Koelmodus: waterkoeling

Besturingssoftware: Cypcut

Ondersteund grafisch formaat: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certificering: CE, ISO, SGS, FDA, BV

Service na verkoop: Ingenieurs beschikbaar voor het onderhoud van machines in het buitenland

Functie: cnc metalen lasersnijmachine

Werkgebied: 1300x3000mm

Laservermogen: 500W ~4000W

Maximaal Bewegende snelheid: 100m/min

Max. Snijsnelheid: 35 m / min

Positioneringsnauwkeurigheid: 0,03 mm

Nauwkeurigheid herpositioneren: 0,02 mm

Min. Lijnbreedte: 0,1 mm

Snijdiepte: 0.2-6mm

Stroomvereisten: 380V/50Hz/16A

Kenmerken

(1) Integratie van volledig geautomatiseerd materiaal richten, nivelleren, laden en snijden

(2) Automatische assemblagelijn voor besparing van mankracht:

(3) Continuïteitsgarantie voor productie en verwerking

(4) Netto spoelmateriaal snijden om de bezettingsgraad van het plaatwerk te verbeteren.

(5) Compacte configuratie en ontwerp met volledige behuizing voor veiliger en milieuvriendelijker gebruik.

(6) Rollend snijplatform om vastlopen van materiaal tijdens het transport van afgewerkt materiaal te voorkomen;

(7) Nivelleermachine is gesynchroniseerd met rollend snijplatform voor materiaaltoevoer, om de onderkant tijdens het materiaaltoevoer vanaf nul te beschermen.

(8) Het automatisch laden van materiaal wordt vergemakkelijkt met een apparaat voor de breedtebegrenzing om te voorkomen dat materialen met een smal of breed formaat uit de baan raken en om uitlijning te garanderen.

Voordeel van cnc-lasermachine voor het snijden van metaal:

1. Uitstekende padkwaliteit: kleinere laserpunt en hoge werkefficiëntie, hoge kwaliteit.

2. Hoge snijsnelheid: snijsnelheid is 2-3 keer dan dezelfde CO2-lasersnijmachine.

3. Stabiele werking: keur de vezellasers van de hoogste wereldimport goed, stabiele prestaties, belangrijke onderdelen kunnen 100.000 uur bereiken;

4. Hoog rendement voor foto-elektrische conversie: Vergelijk met CO2 lasersnijmachine, vezellasersnijmachine hebben drie keer foto-elektrische conversie-efficiëntie.

5. Lage kosten: bespaar energie en bescherm het milieu. Foto-elektrische conversie is maximaal 25-30%. Laag elektrisch stroomverbruik, het is slechts ongeveer 20% -30% van de traditionele CO2-lasersnijmachine.

6. Weinig onderhoud: de transmissie van de vezellijn hoeft niet op lens te wijzen, onderhoudskosten te besparen;

7 Eenvoudige bediening: transmissie van glasvezellijnen, geen aanpassing van het optische pad.