500w 1000w Fiberlasersnijder graveren van metaal voor roestvrij staal te koop, staal 2000 watt snijmachine voor export fiber laser metalen snijmachine 500 watt roestvrij staal fiber lasersnijmachine roestvrijstalen lasersnijmachine cnc fiber metalen lasersnijmachine

Machinetafel Kenmerken:

1.Gantry dubbele aandrijving, die de geavanceerde structuur van de tandheugeltransmissie goedkeurt. Uitgerust met slijptandwiel en tandheugel, en door de precisiecollimator eenmalige meeteenheid. De machine zorgt voor een langdurige hoge snijsnelheid en een zeer nauwkeurige transmissie.

2, de machinetafel machinaal bewerkt door grote planomiller, met tweemaal gloeien op hoge temperatuur en volledig lassen met hoge weerstand, de klant zal op lange termijn worden terugverdiend.

3, Toepasselijke materialen: roestvrij staal, koolstofstaal, gelegeerd staal, verenstaal, aluminium, zilver, koper, titanium en een metalen plaat en pijp.

4, Toepasselijke industrieën: glazen, sieraden, keukengerei, chassis en kast, metalen pijp, lamp en lantaarns, metaalwaren, hardware, precisiemachines, auto-onderdelen, lift, naambord, reclame, elektronica, speelgoed en andere industrieën. Fiberlasermachine 500W Snijden van metalen prijs met 5 jaar garantie roestvrijstalen lasersnijdermachine 500W 1000W 3000W

cnc fiber metalen lasersnijmachine 1325 1530 2040 2060

Technische specificaties, we kunnen ook een model maken volgens het verzoek van de klant;

| Maximum proceshoogte (mm) | 90 | |||

| Effectieve slag | X-as (mm) | 4550 | 3050 | 4050 |

| Y-as (mm) | 1550 | 1550 | 2050 | |

| Z-as (mm) | 100 | |||

| Positie nauwkeurigheid | X-as (mm/m) | 0.03 | ||

| Y-as (mm/m) | 0.03 | |||

| Z-as (mm/m) | 0.01 | |||

| Herhaald nauwkeurigheid | X-as (mm) | 0.02 | ||

| Y-as (mm) | 0.02 | |||

| Z-as (mm) | 0.005 | |||

| Snelle positionering Snelheid | X-as (m/min) | 80 | ||

| Y-as (m/min) | 80 | |||

| Z-as (m/min) | 30 | |||

| Max snijsnelheid | 30m / min | |||

| Maximale snijdikte | afhankelijk van laservermogen | |||

| Energieverbruik | afhankelijk van laservermogen | |||

| Beschermingsniveau | IP54 | |||

| Machinegewicht (ton) | 4.9 | 4.5 | 5.3 | |

| Maat L*B*H (mm) | 5820*2285*1346 | 4516*2220*1346 | 5628*2950*1346 | |

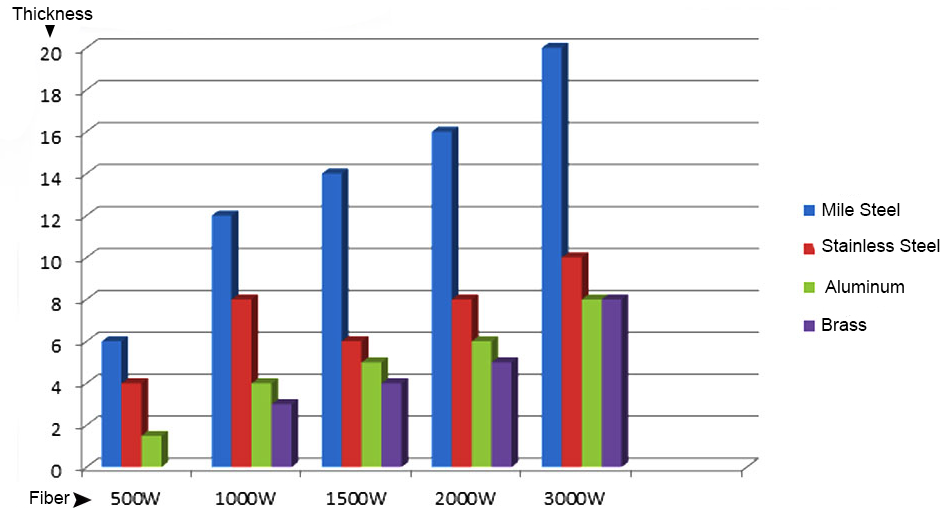

Snijdiktetabel:

Onze diensten

(1) Twee jaar kwaliteitsgarantie, de machine met hoofdonderdelen (exclusief de verbruiksartikelen)

worden kosteloos gewijzigd als zich een probleem voordoet tijdens de garantieperiode.

(2) Gratis levenslang onderhoud.

(3) Gratis training in onze fabriek. CNC automatische pallet dubbele drive optie fiberlasersnijder

(4) Elke dag 18 uur on-line service, gratis technische ondersteuning.

(5) Machine is aangepast vóór levering. We zullen machine foto's maken en maken

machine werkt afbeelding voor u, na uw akkoord te hebben gekregen, dan zullen we een schip boeken.

(6) Technische dienstverlening aan de deur (we hebben professionele ingenieurs om machines aan te bieden

installatie inbedrijfstelling en onderhoud).

(7) Als u problemen ondervindt tijdens uw gebruik. U hebt onze technicus nodig om te beoordelen waar de

probleem is en u helpen om het op te lossen. We kunnen teamviewer en skype van cam tot voorzien

al uw problemen opgelost.

FAQ

FAQ

Q1. Handelsbedrijf of fabrikant?

A: Wij Accurl-laser zijn fabrikant, welkom om onze fabriek te bezoeken!

Q2. Is het eenvoudig te bedienen voor de nieuwe gebruiker?

A: Het is heel eenvoudig, we bieden u bedieningsvideo aan, ook onze aftermarket-technicus kan u helpen via Wechat, WhatsApp, Skype-teamviewer enz.

Q3. Wat moet ik doen als de machine in de problemen zit?

A: Zorg ervoor dat alle draden goed zijn aangesloten en houd uw lens en spiegels schoon (alleen voor Yag-lasersnijmachine), controleer vervolgens uw laserbuis en deel details met ons.

V4: Hoe lang duurt het om te leren werken met een lasersnijmachine?

A: Als je in staat bent om basissoftware voor grafisch ontwerp te gebruiken, duurt het maar een paar uur. Er zijn enkele eenvoudige tests op verschillende verwerkingsmaterialen nodig om te leren hoe je de snelheid en het laservermogen kunt aanpassen.

Q5: Is het schadelijk voor het menselijk lichaam tijdens gebruik?

A: Het is niet schadelijk, zolang de laser niet rechtstreeks op de huid en ogen schiet. 500 watt roestvrijstalen vezellasersnijmachine

Om u een beter aanbod te kunnen doen, verzoeken wij u mij hieronder uw wensen te laten weten:

1) Wat zijn de materialen die u wilt snijden?

2) De dikte van elk snijmateriaal? maximale/gebruikelijke dikte.

3) Wat is de maat van het metaal dat u wilt snijden?

4) Wat zijn de eindproducten?

5) Bent u eindgebruiker of machineverdeler?