Productomschrijving

De ACCURL® abrasieve waterstraalmachine is een hogedruk waterstraalmachine die gebruik maakt van recht watersnijden of abrasief waterstraalsnijden om verschillende soorten materiaal te snijden. De ACCURL® is een heavy-duty precisie, geslepen kogelomloopspindel ontworpen systeem voor maximale precisie en stijfheid. De ACCURL® is gebouwd volgens de strengste normen in de gereedschapswerktuigindustrie. .

De ACCURL® gebruikt het waterstraal hogedruk-snijproces om materiaaldiktes te snijden van een meter tot 8 ".

De ACCURL® zal materiaal snijden zoals aluminium, pantserplaat, messing, tapijt, koper, glas, graniet, leer, marmer, zacht staal, plastic, roestvrij staal, steen, tegels, titanium ...

Perfect waterstraalsnijden :

ACCURL®-waterstraalbewerking wordt bereikt door een groot volume water onder hoge druk door een kleine opening in het snijmondstuk te persen. De versnelde stoom water die het mondstuk verlaat, heeft invloed op het materiaal en start het snijproces. Kerf uit de versnelde waterstroom is extreem smal. Deze druk wordt vervolgens geconcentreerd in een klein gebied op het materiaal dat het materiaal begint te eroderen. Zachter materiaal kan worden gesneden met waterdruk. Hardere materialen vereisen het gebruik van een schurend toevoersysteem, zoals metaalsnijden. Het schuurmiddel wordt geïntroduceerd in de hogedrukwaterstroom, die vervolgens de erosie van de hardere materialen start. Hoewel waterstraalbewerking het langzaamste snijproces is, zijn er duidelijke voordelen die zwaarder wegen dan het tempo:

• Geen warmte-beïnvloede zone

• Geen mechanische spanningen

• Zeer smalle kerf

• Geen secundaire operaties nodig

•Glad oppervlak

• Kan verschillende materialen snijden

• Kan zeer gedetailleerde onderdelen verwerken

• Minimaal materiaalverlies

•Milieuvriendelijk

Hoofdfuncties

Het snelle, efficiënte en nauwkeurige ACCURL® Center biedt topprestaties bij het bewerken van complexe onderdelen uit vele materialen met waterstraal. Van eenvoudige metalen tot complexe composieten, het 4 ′ 7 ”vierkante snijgebied van de beproefde is ideaal voor snelle prototyping en just-in-time fabricage van kleine tot middelgrote onderdelen. Met eenvoudige opspanning en gemakkelijke toegang tot de snijtafel worden de insteltijden aanzienlijk verkort, waardoor de productiviteit en winstgevendheid toenemen.

• De hoogste snijsnelheden en de beste precisie vergeleken met welke abrasivejet in de branche dan ook en wordt ondersteund door onze exclusieve NAIKY PCIMC-6A®-software met echte snijgegevens

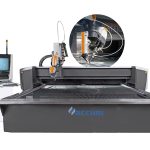

• Programmeerbare gemotoriseerde Z-as met een nauwkeurige ACCURL® 5i-mondstukconstructie kan de snijproductiviteit en procesefficiëntie verhogen

• Tilt-A-Jet® taps compenserende abrasivejet-snijkop (beschikbaar als optie)

• Precisie XY-as stevig gemonteerd op de snijtafel

• Voorbelaste lineaire lagers en precisie kogelomloopspillen

• Onderhoudsarm en zeer betrouwbaar, hard loodgieterswerk in schaarstijl

• Aandrijfsysteem afgedicht tegen water, vuil en gruis

• Gemakkelijke toegang voor de operator tot het werkgebied

• Hoogrenderende Generation 4 USA Hypertherm ® pompsystemen verkrijgbaar in 30, 40 of 50 pk met een bedrijfsrendement tot 90%

• Robuust en nauwkeurig ontwerp voor snijden met nauwe toleranties en betrouwbare werking

• Snelle waterpeilcontrole voor stil en schoon zagen onder water

• Bulk Abrasive Delivery System transporteert granaat van de grote hopper van de assemblage naar de Zero Downtime Hopper op de Z-as

• Optioneel Variable Speed Solids Removal System (VS-SRS) ontworpen voor zwaar industrieel gebruik verhoogt de uptime door geautomatiseerde verwijdering van vaste stoffen

• Wordt geleverd als een volledig voorgemonteerd en in de fabriek getest systeem

Details:

Machineframe

De MAX-serie heeft een carrosserie met elektrische componenten die stevig in de carrosserie van de machine zijn ingebouwd. Dit unieke monoblokontwerp zorgt voor een eenvoudige installatie en de flexibiliteit om het systeem naar een groot aantal locaties te verplaatsen.

Servo-aandrijving en motor

De geïmporteerde servomotor (Y-as aangedreven door twee servomotoren) zorgt samen met het geavanceerde planetaire verloopstuk voor een stabiele, nauwkeurige en betrouwbare aandrijving.

Kogelomloopspindel met roterende moer

Precisie kogelomloopspindels hebben een hoge betrouwbaarheid en herhaalbaarheid die de prestaties en nauwkeurigheid verhogen.

Snijkoppen VS Hypertherm

De IDE-kop is een eenvoudig te gebruiken stuk. Het enkele snijkopstuk bestaat uit een huis, een diamanten opening en een mengkamer. Het heeft een inlaat van 90 graden die voorkomt dat er zich schuurmiddel ophoopt aan het hoofd. Het heeft een vlakke afdichting, zelfs op de mondstukbuis, waardoor het risico op breuk van de opening wordt uitgesloten. Het is erg handig voor bedrijven met meerdere waterjetoperatoren

snelle details

conditie: nieuw

Plaats van herkomst: Anhui, China (vasteland)

Merknaam: ACCURL

Modelnummer: MAX-WJ-2515D, MAX-WJ-2515D

Voltage: 380V 220V Optioneel

Nominaal vermogen: 7,5 kW

Afmeting (L * B * H): 3880 * 2150 * 2000 mm

Gewicht: 6500 kg

Certificatie: CE ISO SGS FDA

Garantie: 3 jaar garantie

Service na verkoop: Ingenieurs beschikbaar voor het onderhoud van machines in het buitenland

Versterkerconstructie: Hypertherm USA

Gantry type: Tafel

Effectief snijgebied: 1500x3000 mm

AC servobestuurder: MITSUBISHI uit Japan

Kogelomloopspindel en lineaire geleiderail: HIWIN van TAIWAN

Schakelventiel: Rexroth uit Duitsland

Hoofdmotor van pomp: Siemens uit Duitsland

CNC-controller: AI, DST, DWG, DXF, DXP, LAS