snelle details

snelle details

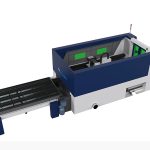

Toepassing: lasersnijden

conditie: nieuw

Lasertype: vezellaser

Toepasselijk materiaal: metaal

Snijdikte: 0-30 mm

Snijgebied: 1500 * 3000 mm

Snijsnelheid: 35 m / min

CNC of niet: Ja

Koelmodus: waterkoeling

Besturingssoftware: Bodor Pro

Ondersteund grafisch formaat: AI, DXF, PLT

Plaats van herkomst: Shandong, China (vasteland)

Merknaam: Bodor

Modelnummer: P3015

Certificering: CE, ISO, SGS, FDA, BV, TUV

Service na verkoop: Ingenieurs beschikbaar voor het onderhoud van machines in het buitenland

Laservermogen: 500W / 1000W / 1500W / 2000W / 3000W / 4000W

Trefwoord: lasersnijder

Laserbron: IPG / MAX

Garantie: 3 jaar

Grootte: 9950 * 3050 * 2200 mm

Gewicht: 11000 kg

Werkgebied: 1500 * 3000 mm

Levensduur: meer dan 20 jaar

Koeling: waterkoeling

Continue werktijd: 24 uur

Kenmerken van onze lasersnijmachine

1. volledige beschermhoes

Milieuvriendelijk en Gezond

Volledig gesloten beveiliging verbetert het gebruik van beveiliging; laserbeschermingsglas isoleert laserstraling voor mensen; automatisch opvangsysteem voor rook en stof is milieuvriendelijk; intelligent monitoringsysteem vermindert het aantal ongevallen, waardoor we genieten van schoonheid en gezondheid tijdens het snijproces.

2. twee automatische uitwisselingsplatforms

tijdbesparend en inspannend

Snelle uitwisseling tussen twee platforms verbetert de werkefficiëntie aanzienlijk. Tandheugel-transmissiesysteem heeft een betere stijfheid en hogere nauwkeurigheid, waardoor de invoertijd wordt bespaard en de werking efficiënter wordt.

3. Uiterlijkontwerp

Omringd door zilverkleurige bakverf, gecoördineerd met diamantgeslepen gehard glas en alpine wit plaatwerk, wordt het internationale ontwerp van de machine geaccepteerd door wereldwijde consumentengroepen. De werkplek is netjes, ordelijk en ruimtebesparend.

4. gietijzeren bed

Integraal gevormd, verwerp splicing

Gebruik van gietijzer met vlokgrafiet, waarvan de laagste treksterkte 200 MPa is. Hoog koolstofgehalte, hoge druksterkte en hoge hardheid. Sterke schokabsorptie en slijtvastheid. Goede werp- en snijprestaties. Uitstekende smering, corrosieweerstand en dimensionale stabiliteit. Lage thermische gevoeligheid en gevoeligheid van de bedopening verminderen het verlies van apparatuur bij het gebruik, zodat de nauwkeurigheid van de machine lange tijd kan behouden en geen vervorming in een levenscyclus.

5. Auto focus laserkop

Maak uw handen vrij, geniet van autofocus

(1) Autofocus

Van toepassing op verschillende brandpuntsafstanden, die worden bestuurd door machinebesturingssysteem. Het brandpunt wordt automatisch aangepast tijdens het snijproces om het beste snijeffect van metaalplaten met verschillende diktes te bereiken.

(2) Gratis

De brandpuntsafstand wordt geregeld door het besturingssysteem. We hoeven geen handmatige regeling uit te voeren, waardoor fouten of fouten veroorzaakt door handmatige bediening effectief worden vermeden.

(3) Snel

Het kan automatisch de meest geschikte brandpunten in het werkproces aanpassen, waardoor de snijsnelheid aanzienlijk wordt verbeterd;

Bij het vervangen van verschillende materialen of vellen met verschillende diktes, moet de handmatige focuslaserkop de brandpuntsafstand handmatig aanpassen, zeer inefficiënt; autofocus laserkop kan systeemopslagparameters automatisch lezen, zeer efficiënt;

(4) Nauwkeurigheid:

Door de brandpuntsafstand van de perforatie te vergroten, de brandpuntsafstand van de perforatie afzonderlijk in te stellen en de brandpuntsafstand af te snijden, wordt de snijnauwkeurigheid verbeterd.

(5) Duurzaam

Ingebouwde dubbele waterkoelingsstructuren kunnen zorgen voor een constante temperatuur van collimerende en scherpstellende componenten, voorkomen dat lenzen oververhit raken en verlengen de levensduur van lenzen.

Verhoogde collimatiebeschermende lens en focusbeschermende lens, bescherm de belangrijkste componenten zorgvuldig.

6. Weergave van besturingssysteem

Elegante verschijningscurve

De eerste ter wereld die UI-ontwerp gebruikt, waardoor het display kan reageren op de verwerkingstabel, waardoor de verwerking intuïtiever wordt. Elegante rondingen passen precies in het machinelichaam. Sterk waterdicht ademend systeem creëert de beste ruimte, waardoor de bediening gemakkelijker wordt. Diamantsnijproces en HD-plasma-gehard glas maken het scherm voortreffelijker en comfortabeler in gebruik.

7. Gegoten aluminium dwarsbalk

Integraal gieten onder druk van stalen mal, licht, flexibel en efficiënt

Na kunstmatige veroudering, oplossingsbehandeling en afwerking bezit de dwarsbalk goede integriteit, stijfheid, oppervlaktekwaliteit, taaiheid en vervormbaarheid. De metaalkenmerken van aluminiumlegering van lichtgewicht en sterke stijfheid zijn nuttig voor snelle bewegingen bij de verwerking, en hoge flexibiliteit is gunstig voor het snel snijden van verschillende afbeeldingen op basis van hoge nauwkeurigheid. Lichte dwarsbalk kan apparatuur een hoge werksnelheid geven, waardoor de verwerkingsefficiëntie wordt verbeterd om de verwerkingskwaliteit te garanderen.

| Werken grootte | 1500 * 3000mm |

| Laservermogen | 1000/1500/2000/3000 / 4000W |

| Machinegrootte | 9950 * 3050 * 2200mm |

| Gewicht | 11000Kg |

| Max bewegende snelheid | 100m / min |

| Max snijsnelheid | 35 m / min |

| Min lijnbreedte | 0.1mm |

| Zaagdiepte | 0.2-6mm |

| Koeling manier | Waterkoeling |

| Rijden en transmissie manier | Geïmporteerde servomotor |

| Continue werktijd | 24 uur |

| Nauwkeurigheid positionering | 0.03mm |

| Verplaats nauwkeurigheid | 0.02mm |

Toepassing materialen:

Het is geschikt voor het snijden van koolstofstaal, roestvrij staal, aluminium, koper en gelegeerde metalen materialen

Toepassingsindustrieën:

De apparatuur voldoet aan de vereisten voor de verwerking van onderdelen van de meeste industrieën, de werknauwkeurigheid is stabiel. Op dit moment zijn lasersnijmachines op grote schaal gebruikt in elektronica, elektrische, mechanische hardware, nieuwe energie lithium, verpakking, zonne-energie, LED, auto-industrie en andere industrieën.

snelle details

snelle details